Pemserter Series4 metal press

If you decide to buy equipment at a low price, make sure that you communicate with the real seller. Find out as much information about the owner of the equipment as possible. One way of cheating is to represent yourself as a real company. In case of suspicion, inform us about this for additional control, through the feedback form.

Before you decide to make a purchase, carefully review several sales offers to understand the average cost of your chosen equipment. If the price of the offer you like is much lower than similar offers, think about it. A significant price difference may indicate hidden defects or an attempt by the seller to commit fraudulent acts.

Do not buy products which price is too different from the average price for similar equipment.

Do not give consent to dubious pledges and prepaid goods. In case of doubt, do not be afraid to clarify details, ask for additional photographs and documents for equipment, check the authenticity of documents, ask questions.

The most common type of fraud. Unfair sellers may request a certain amount of advance payment to “book” your right to purchase equipment. Thus, fraudsters can collect a large amount and disappear, no longer get in touch.

- Transfer of prepayment to the card

- Do not make an advance payment without paperwork confirming the process of transferring money, if during the communication the seller is in doubt.

- Transfer to the “Trustee” account

- Such a request should be alarming, most likely you are communicating with a fraudster.

- Transfer to a company account with a similar name

- Be careful, fraudsters may disguise themselves as well-known companies, making minor changes to the name. Do not transfer funds if the company name is in doubt.

- Substitution of own details in the invoice of a real company

- Before making a transfer, make sure that the specified details are correct, and whether they relate to the specified company.

Seller's contacts

United Kingdom

United Kingdom

and sizes up to M12 / 1/2″ into aluminum or plastics

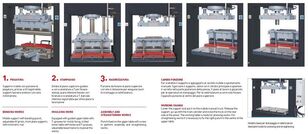

The Series 4 press is able to place all PEM self clinch and broaching fasteners. Designed for ease of use

fast changeover and speed of production the Series 4 is an ideal choice for most manufacturing requirements. Now updated with a new integral stand/locking cabinet

laser pointer to speed up assembly on blind side applications and a counter to help keep an eye on production throughput the Series 4 has all of the features one could need

The series 4 is the fastest press available today. This means that a batch of product put through a PEMSERTER will be completed long before the same batch on a competitor press even one boasting a continuous feed bowl and costing much more money. To speed things up even more the press can be mated up with a QX turret which allows four tool set ups to be mounted at the same time reducing changeover time to virtually zero

If you would like to put a Series 4 to the test contact us to arrange a trial on your own premises with your own components and see for yourself how a Series 4 could improve your production efficiency

Insertion force adjustable from 1.8 to 53.4 kN / 400 lbs. to 6 tons

Pneumatic power for speed

consistency and simple operation. Requires standard compressed air only

Integral point-of-operation safety

Large parts tray

Rapid tooling changeover

perfect for short production runs

One-year parts warranty and two-year limited warranty on pneumatic components

Integral stand and tool cupboard

Optional anvil holders are also available to purchase for the Series 4 manual press which enable access to difficult to reach applications

The Pemserter Series 4 Press with Automatic Feed

provides 6 tons of force and has a 45.7 cm / 18″ throat depth that provides clearance for a variety of chassis configurations. It is designed to install self-clinching nuts

studs

and standoffs in sizes M2.5 to M6. Features and Benefits

Pneumatic power for speed

consistency

and simple operation

Uses the same tooling components as the Series 2000® and Series 3000™ Presses

Automatically installs nuts

studs

and standoffs from M2.5 to M6

Pneumatic and PLC logic control system

Touch-screen for operator friendly operation

Vibratory feeder bowl for automatic fastener feeding

Integral point-of-operation safety

Insertion force adjustable from 1.8 to 53.4 kN / 400 to 12,000 lbs

Laser pointer

stroke counter

and lockable cabinet for tool and accessorie storage

Other models of Pemserter we have sold and have forsale

Series 3000 Press

Series 2000 Press

Series 2000 XT Press

Series 2000 Base Press

Series 4 Press

Series 4 Press Autofeed

Series P3 Press

Series Micro-mate

Used sheet metal fastener machine for sale / Rivet insertion machine for sale